-

tel:

+86 18017382810 -

email:

printyoung@gmail.com

Automatic Pile Turner and Stacking Machine for Flute Laminator

description1

Zipper closure

1/5 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the

body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them

in

place during workout

Automatic Pile Turner and Stacking Machine for Flute Laminator

PRY-1450S Auto Pile Turner and Stacking Machine

Features

Auto Pile Turner and Stacking Machine is the special accessory products for sheet to sheet laminating machines and can be connected with any of manufacturer’s laminating machine. This integrative equipment can auto make the laminated papers to piles according to specified number.With collecting,piling,intermittent turning and stacking functions,realize collected paper front and backside placed stacking,effectively prevent laminated paper curving and manpower-saving for labor collecting strength.

Auto Collecting

Front and Back Placed Stacking

Collecting Orderly

One Key Operation

Fault Detection

Easy Connecting

Space Saving

Simple and easy to learn

Save time and effort

Front and Back Placed Stacking

Collecting Orderly

One Key Operation

Fault Detection

Easy Connecting

Space Saving

Simple and easy to learn

Save time and effort

Technical Parameters

|

Model

|

1450S

|

1650S

|

|

Max Sheet Size

|

1450X1450mm

|

1650X1450mm

|

|

Min Sheet Size

|

500X500mm

|

500X500mm

|

|

Overall

|

6830X2760X2950mm

|

6830X3160X2950mm

|

|

Weight

|

3700KGS

|

4000KGS

|

|

Power

|

6KW

|

6KW

|

The SPARE PART LIST for flip flop machine (FREE):

1.Bearing CY16 ----- 2PCS

2.The circular belt Φ ----- 5Meters

3.Solenoid valve 4V31010A ----- 1PC

4.Synchronous belt ----- 5M*400*20: 1PC

5.Synchronous belt ----- 5M*450*20: 1PC

6.Synchronous belt ----- 8M*672*35: 1PC

7.The copper nut ----- 1PC

8.Approach switch ----- 1PC

9.Cylinder regulating valve Φ8 ----- 1PC

10.The air pipe Φ8 ----- 1PC

11.The air pipe Φ12 ----- 1PC

12.The air pipe contact Φ8 ----- 1PC

13.The air pipe contact Φ12 ----- 1PC

1.Bearing CY16 ----- 2PCS

2.The circular belt Φ ----- 5Meters

3.Solenoid valve 4V31010A ----- 1PC

4.Synchronous belt ----- 5M*400*20: 1PC

5.Synchronous belt ----- 5M*450*20: 1PC

6.Synchronous belt ----- 8M*672*35: 1PC

7.The copper nut ----- 1PC

8.Approach switch ----- 1PC

9.Cylinder regulating valve Φ8 ----- 1PC

10.The air pipe Φ8 ----- 1PC

11.The air pipe Φ12 ----- 1PC

12.The air pipe contact Φ8 ----- 1PC

13.The air pipe contact Φ12 ----- 1PC

Configuration

Paper Separating System

Driving wheel and laminating press belt joint to transmit power.Laminated paper be stacked down to down pallet by driving wheel and synchronous belt,when reach the specified number,separating rod lift and separate the paper.

Down Push System

Driven by the cylinder two pawl forward movement,push the set up quantity paper into a turnover device.

Turning System

Using the automatic clamping system to make paper front and back alternately placed,make sure the laminated paper smooth and stiff,convenient for subsequent production line.

Up Push System

Using The motor drives the chain to drive the upper push plate to move forward and backward pushing the lifting paper into

collecting system and waiting to be piled.

collecting system and waiting to be piled.

Piling System

Reciprocating motion of four splint patting the collected paper orderly,ensure the collecting neat

Collecting System

When the paper stacking to 1.7M in height, collecting platen automatic drop,hydraulic car will pull out the whole stack of paper,at the same time the vice paper collecting table automatic work,complete non-stop collecting finished.

Electronic Unit

All parts adopt well-known brand, reasonable program design, working by one key to complete the operation,automatic fault

detection.

detection.

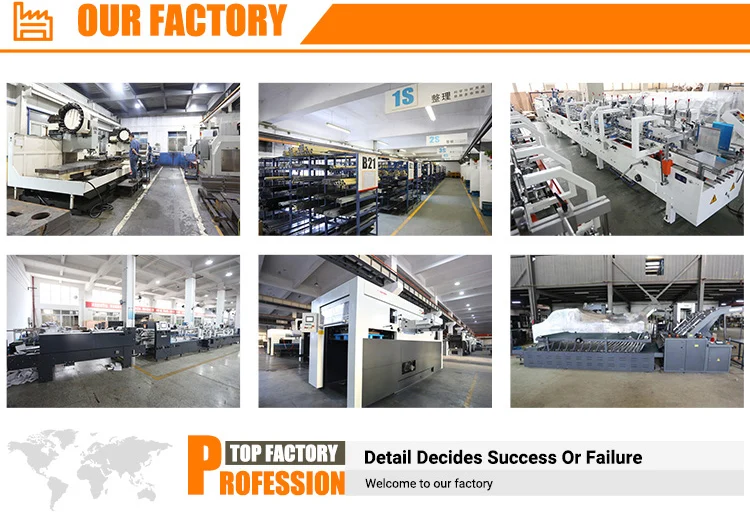

Q1.Are you a manufacturer or a trading company?

A:Our shanghai office is mainly doing export.We have our own factory in Wenzhou, Zhejiang Province.

Q2.What is the machine warranty?

A:One year.After the warranty,we still provide technical support to buyer at low cost.

Q3.What is the production time while placing order?

A:Normally about 10-20 days.

Q4.What is the delivery time?

A:15-30days after deposit.

Q5.Can your company handle shipping for customers?

A:Yes,just give us destination sea port or container yard.

Q6.Does the packing strong?

A:Yes.Adopts moisture-proof and shock-proof packaging which is suitable for long-distance road transportation and various types of weather conditions.A full set of maintenance and operation manuals is included.

Q7.How about the machine installation and training?

A:1)We provide training in our factory for free;2)We can send technicians (engineers) to your factory for installation and training.You shall pay the round trip air fare and accommodations,plus each technician charges USD100/per day.

Q8.Do you have machines in stock?

A:For standard model,we have a large quantity in stock.For special model,we need 20-30 days to produce it for you.

Q9.How can you assure the machines’ quality?

A:Each machine will be test running at least 24 hours before delivery to assure the quality.And during the warranty,we will give spare parts for free if machine has any problem.

Q10.Do you inspect machines or test running before packing?

A:Of course we do.We have QC department to debug the machine before packing.If you want to use specific material to do the test running,you need to pay for the cost of the material.

Q11.What’s the payment term?

A:T/T 30% in advance,the balance shall be paid before delivery.We also accept payment by West Union or L/C at sight.

Q12.Do you accept factory visiting?

A:Warmly welcome for your visiting.

Q13.How many years are you in printing field?

A:The Shanghai company since in 2008,the factory is more than 25years.

Q14.How many clients do you have?

A:We have sold our machines to about 60 countries.We have agents in South Africa,Morocco and Italy.