-

tel:

+86 18017382810 -

email:

printyoung@gmail.com

YW-F Automatic Deep Paper Concave Convex Spot Embossing Machine

description1

Zipper closure

1/5 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the

body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them

in

place during workout

YW-F Automatic Deep Paper Concave Convex Spot Embossing Machine

YW-F Automatic Paper Embossing Machine

Features

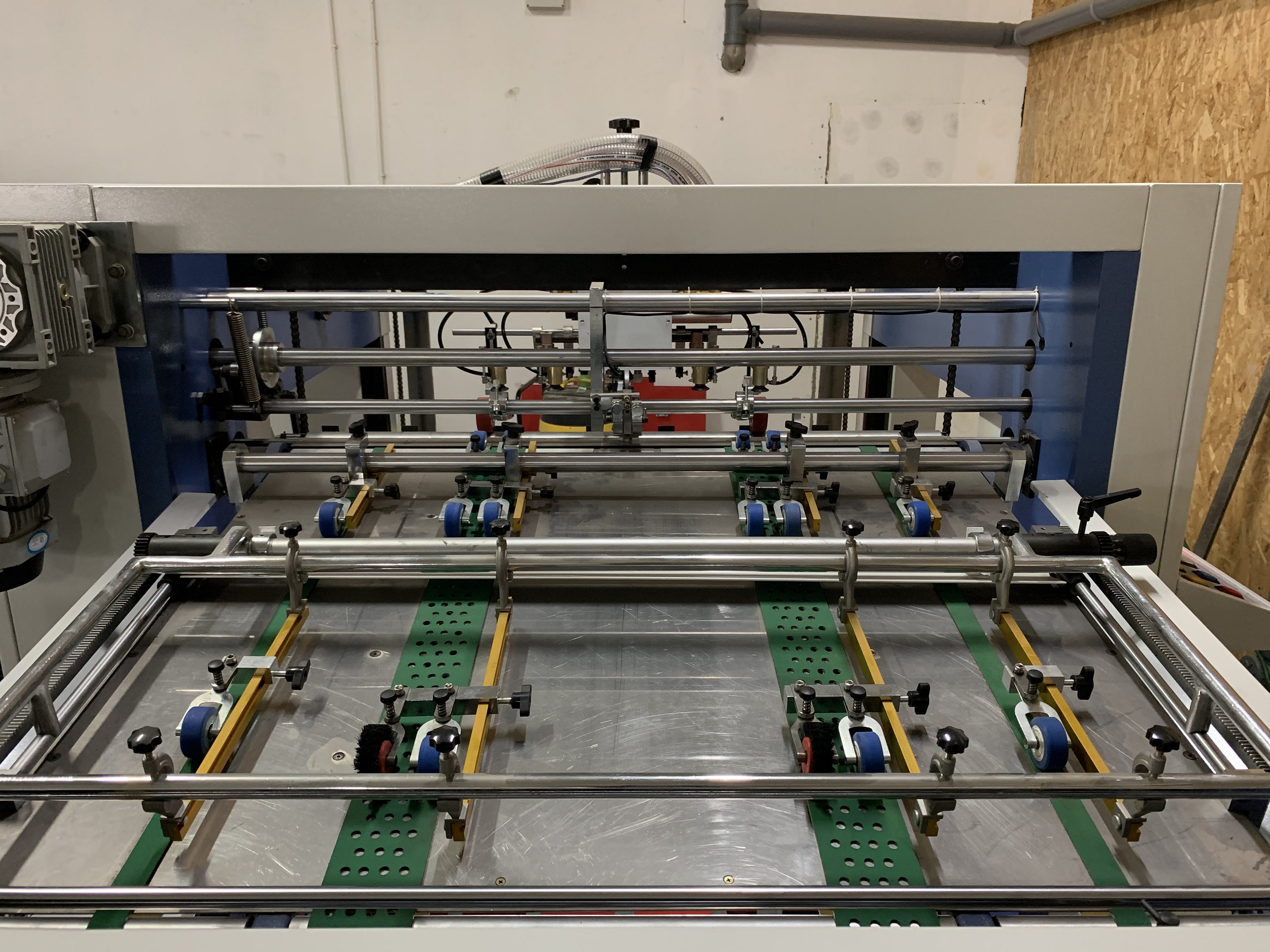

This machine is full-automatic equipment for concave and convex embossing.

It can finish dull polish,UV,dioptric at one time without ink.

The embossing press adopts cylinder-to-cylinder structure with steady pressure.

The embossing press adopts cylinder-to-cylinder structure with steady pressure.

The pressure can easily adjust with different thickness of paper.

The wheel is designed with quick warm-up time and with temperature control ranges 80-150℃.You can easily adjust pressure with high precision.

The machine is applied to embossing and ink-free printing,pollution-free,low power and odorless;making different graphic images which can be special designed for customer.

The wheel is designed with quick warm-up time and with temperature control ranges 80-150℃.You can easily adjust pressure with high precision.

The machine is applied to embossing and ink-free printing,pollution-free,low power and odorless;making different graphic images which can be special designed for customer.

Such as:reflection,ice,laser,3D,buckram,any kinds patterns etc.

Main Characteristics:Safety,Energy Saving,High Efficiency

A.Inovance frequency conversion speed regulating motor,drive the host,the whole machine has a Mitsubishi PLC programmable controller centralized control mode,can automatically detect the status of the job,Europe,America,Japan,Taiwan,and other electronic components, human-based principle,in accordance with safety standards makes the safety of the whole machine more strong and easy for operation.

B.Set up the perfect boot alarm bell alarm system,prompt the operator to leave the safety area,boot safer to avoid casualties.Imported pneumatic clutch automatic separation of downtime,reduce the waste of paper,protect the safety of the operator and equipment.

C.Elaborate pre-stack of the paper device,the unique transfer paper,greatly reducing the pile of paper,improve the efficiency of the use of the machine,the efficiency is greatly increased.

D.A complete set of electrical components are imported products,greatly improve the stability of the electric system,reducing maintenance and testing frequency and the difficulty.

E.Driving system:using high new torque gear,NSK,IKO bearings imported from extensive use of the fine,reduce the machine running at high speed under the oscillation and noise, guarantee the stable running.

F.Mainframe wallboard and base of imported advanced resin sand nodular cast iron,by CNC center precision machining,to ensure reliable long-term stable operation,able to withstand 650 tonnages when the pressure force is stable.

G.The heart component adopts the forced lubrication system.

H.Provide long-term,perfect technical training,a year of free maintenance,to ensure that customers can fully grasp equipment production technology,complete the function of equipment should have.Customers to use low maintenance costs.

A.Inovance frequency conversion speed regulating motor,drive the host,the whole machine has a Mitsubishi PLC programmable controller centralized control mode,can automatically detect the status of the job,Europe,America,Japan,Taiwan,and other electronic components, human-based principle,in accordance with safety standards makes the safety of the whole machine more strong and easy for operation.

B.Set up the perfect boot alarm bell alarm system,prompt the operator to leave the safety area,boot safer to avoid casualties.Imported pneumatic clutch automatic separation of downtime,reduce the waste of paper,protect the safety of the operator and equipment.

C.Elaborate pre-stack of the paper device,the unique transfer paper,greatly reducing the pile of paper,improve the efficiency of the use of the machine,the efficiency is greatly increased.

D.A complete set of electrical components are imported products,greatly improve the stability of the electric system,reducing maintenance and testing frequency and the difficulty.

E.Driving system:using high new torque gear,NSK,IKO bearings imported from extensive use of the fine,reduce the machine running at high speed under the oscillation and noise, guarantee the stable running.

F.Mainframe wallboard and base of imported advanced resin sand nodular cast iron,by CNC center precision machining,to ensure reliable long-term stable operation,able to withstand 650 tonnages when the pressure force is stable.

G.The heart component adopts the forced lubrication system.

H.Provide long-term,perfect technical training,a year of free maintenance,to ensure that customers can fully grasp equipment production technology,complete the function of equipment should have.Customers to use low maintenance costs.

Technical Parameters

|

YW-F Paper Embossing Machine

|

||

|

Model

|

YW-102F

|

YW-110F

|

|

Max. Paper Size

|

1020x720mm

|

1100x780mm

|

|

Min. Paper Size

|

450x290mm

|

450x290mm

|

|

Max. Embossing Area

|

1020x700mm

|

1100x770mm

|

|

Paper Thickness

|

100~1000gsm

|

100~1000gsm

|

|

Gripper Edge Size

|

2.0mm

|

2.0mm

|

|

Embossing Plate Edge Size

|

55.0mm

|

55.0mm

|

|

Embossing Plate Size

|

1020x830x0.8~1.2mm

|

1100x880x0.8~1.2mm

|

|

Blanket Size

|

1020x950x1.8mm

|

1100x980x0.8~1.2mm

|

|

Max. Speed

|

5000R.P.H

|

5000R.P.H

|

|

Tempreture Range

|

50-200℃

|

50-200℃

|

|

Temp Control Heating Area

|

11pcs/ 4 control areas

|

11pcs/4 control areas

|

|

Feeding Height

|

1250mm

|

1250mm

|

|

Delivery Height

|

1150mm

|

1150mm

|

|

Power Supply

|

380v 50/60HZ

|

380v 50/60HZ

|

|

Total Power

|

18.0kw

|

19.0kw

|

|

Total Weight

|

7000kg

|

7400kg

|

|

Overall Dimension

|

5800x2000x1800mm

|

5950x2100x1800mm

|

|

Roller

|

|

|

Diameter of Embossing Roller

|

455.5mm

|

|

Diameter of Liner Plate Roller

|

454.5mm

|

|

Printing Plate Roller

|

|

|

Thickness of Roller Surface

|

65mm

|

|

Diameter of Shaft Head

|

160mm

|

|

Embossing Roller

|

|

|

Thickness of Roller Surface

|

65mm

|

|

Diameter of Shaft Head

|

160mm

|

|

Wall Version

|

|

|

Height

|

1125mm

|

|

Thickness

|

73mm

|

|

Precision of Machine

|

|

|

Accuracy

|

±0.2mm

|

|

Temperature

|

±2℃

|

|

Pressure

|

±0.05mm

|

Configuration

Feeder and Paper Feeding Department

1.All major parts of the high-speed paper suction head come from importing countries, domestic assembled can be adjusted freely according to the paper situation.

1.All major parts of the high-speed paper suction head come from importing countries, domestic assembled can be adjusted freely according to the paper situation.

Feida head is good to go from higher to lower and visa versa gsm of the material.

2.Adopt four to four strong suction Feida,the suction head can be adjusted with the deflection of the paper all kinds of paper’s point of view,both sides have a blower, convenient paper separation, ensure smooth paper.

3.Three collision device, safe and reliable.

4.Tilting transmission platform,more suitable for high-speed transmission and localization of tissue paper.

5.Feed wheel lugs MAO linked to adjust and improve efficiency.

6.Feed configuration on both sides of the push and pull gauge device,the side gauge without having to remove or install any parts can complete push-pull transformation,using magic eye detection which is more accurate.

7.Equipped with double tension testing device,testing parking,reduce the waste of paper.

8.The unique feeding device,equipped with pre-loaded with paper,greatly improving the work efficiency.

Roller Stamping Parts

1.Host worm gear,turbine,adopt advanced forging process,after quenched and tempered the precision grinding processing,greatly improving the service life of the machine is the key driving part.

2.Mainframe wallboard and base to choose the dense baking class the resin sand ductile iron casting,ensure the machine under high speed,stable operation for a long time,under the forces large tons of stress remains stable.

3.Impression cylinder through the high precision process,to ensure stable operation under the big tonnage pressure for a long time use;Bearing the brand imported from Japan NSK, effectively improve the service life of the equipment,better improve stability.

4.Advanced CAM structure,optimized the movable tooth gear,improve equipment efficiency, reduce noise.

5.The main motor adopts Taiwan imported brand.

6.Tooth row body with special super-hard aluminum alloy profiles,surface anodize oxidation treatment,can achieve precise positioning in the high-speed operation.

2.Adopt four to four strong suction Feida,the suction head can be adjusted with the deflection of the paper all kinds of paper’s point of view,both sides have a blower, convenient paper separation, ensure smooth paper.

3.Three collision device, safe and reliable.

4.Tilting transmission platform,more suitable for high-speed transmission and localization of tissue paper.

5.Feed wheel lugs MAO linked to adjust and improve efficiency.

6.Feed configuration on both sides of the push and pull gauge device,the side gauge without having to remove or install any parts can complete push-pull transformation,using magic eye detection which is more accurate.

7.Equipped with double tension testing device,testing parking,reduce the waste of paper.

8.The unique feeding device,equipped with pre-loaded with paper,greatly improving the work efficiency.

Roller Stamping Parts

1.Host worm gear,turbine,adopt advanced forging process,after quenched and tempered the precision grinding processing,greatly improving the service life of the machine is the key driving part.

2.Mainframe wallboard and base to choose the dense baking class the resin sand ductile iron casting,ensure the machine under high speed,stable operation for a long time,under the forces large tons of stress remains stable.

3.Impression cylinder through the high precision process,to ensure stable operation under the big tonnage pressure for a long time use;Bearing the brand imported from Japan NSK, effectively improve the service life of the equipment,better improve stability.

4.Advanced CAM structure,optimized the movable tooth gear,improve equipment efficiency, reduce noise.

5.The main motor adopts Taiwan imported brand.

6.Tooth row body with special super-hard aluminum alloy profiles,surface anodize oxidation treatment,can achieve precise positioning in the high-speed operation.

Tooth row of the active chain which adopts special chain,the original tensile processing,and matching,improve the accuracy and stability of the machine and prolong service life.

7.Paper into the mouth using magic eye detection.

8.Top rules can be fine-tuning separately so as to adapt to different papers under the condition of accurate positioning.

Paper Delivery Department

1.Paper damping reduces speed by mechanical pressure to adjust the amplitude of movement and dynamics,various types of paper in the low speed or high speed can be neatly stacked.

2.Tooth row of transmission chain up round buffer device.

The Ministry of Electric Control

1.The machine interface controls integration,a large number of electric switch controls are involved in the operation interface,simple and clear,easy to operate.

2.Programmable controller PLC control operation and fault monitoring and control system of the machine.

3.Electrical components and electrical wiring use the European and American advanced national safety standards.

4.Electrical box ark adopts air cooling devices,effectively guarantee the normal work of the electric control in high-temperature conditions.

7.Paper into the mouth using magic eye detection.

8.Top rules can be fine-tuning separately so as to adapt to different papers under the condition of accurate positioning.

Paper Delivery Department

1.Paper damping reduces speed by mechanical pressure to adjust the amplitude of movement and dynamics,various types of paper in the low speed or high speed can be neatly stacked.

2.Tooth row of transmission chain up round buffer device.

The Ministry of Electric Control

1.The machine interface controls integration,a large number of electric switch controls are involved in the operation interface,simple and clear,easy to operate.

2.Programmable controller PLC control operation and fault monitoring and control system of the machine.

3.Electrical components and electrical wiring use the European and American advanced national safety standards.

4.Electrical box ark adopts air cooling devices,effectively guarantee the normal work of the electric control in high-temperature conditions.

Applications

Packing box for:cosmetics,gift,medicines,cigarette,wine,teas,handbags,etc.

Cards:greeting cards,invitation,cards,special occasion cards,playing cards,etc.

Picture:religious figures and themes,work of art,etc.

Cardboard:width useful on the paper card embossing,spot embossing.

Cards:greeting cards,invitation,cards,special occasion cards,playing cards,etc.

Picture:religious figures and themes,work of art,etc.

Cardboard:width useful on the paper card embossing,spot embossing.

Q1.Are you a manufacturer or a trading company?

A:Our shanghai office is mainly doing export.We have our own factory in Wenzhou, Zhejiang Province.

Q2.What is the machine warranty?

A:One year.After the warranty,we still provide technical support to buyer at low cost.

Q3.What is the production time while placing order?

A:Normally about 10-20 days.

Q4.What is the delivery time?

A:15-30days after deposit.

Q5.Can your company handle shipping for customers?

A:Yes,just give us destination sea port or container yard.

Q6.Does the packing strong?

A:Yes.Adopts moisture-proof and shock-proof packaging which is suitable for long-distance road transportation and various types of weather conditions.A full set of maintenance and operation manuals is included.

Q7.How about the machine installation and training?

A:1)We provide training in our factory for free;2)We can send technicians (engineers) to your factory for installation and training.You shall pay the round trip air fare and accommodations,plus each technician charges USD100/per day.

Q8.Do you have machines in stock?

A:For standard model,we have a large quantity in stock.For special model,we need 20-30 days to produce it for you.

Q9.How can you assure the machines’ quality?

A:Each machine will be test running at least 24 hours before delivery to assure the quality.And during the warranty,we will give spare parts for free if machine has any problem.

Q10.Do you inspect machines or test running before packing?

A:Of course we do.We have QC department to debug the machine before packing.If you want to use specific material to do the test running,you need to pay for the cost of the material.

Q11.What’s the payment term?

A:T/T 30% in advance,the balance shall be paid before delivery.We also accept payment by West Union or L/C at sight.

Q12.Do you accept factory visiting?

A:Warmly welcome for your visiting.

Q13.How many years are you in printing field?

A:The Shanghai company since in 2008,the factory is more than 25years.

Q14.How many clients do you have?

A:We have sold our machines to about 60 countries.We have agents in South Africa, Morocco and Italy.